Mining Industry

From drillers to earthmovers. Rock dusters to excavators. Reshaping vast contours. Unearthing and redistributing massive amounts. Your equipment endures heavy loads and long hours. For that reason, we’ve formulated products to protect your gear from below ground to the surface.

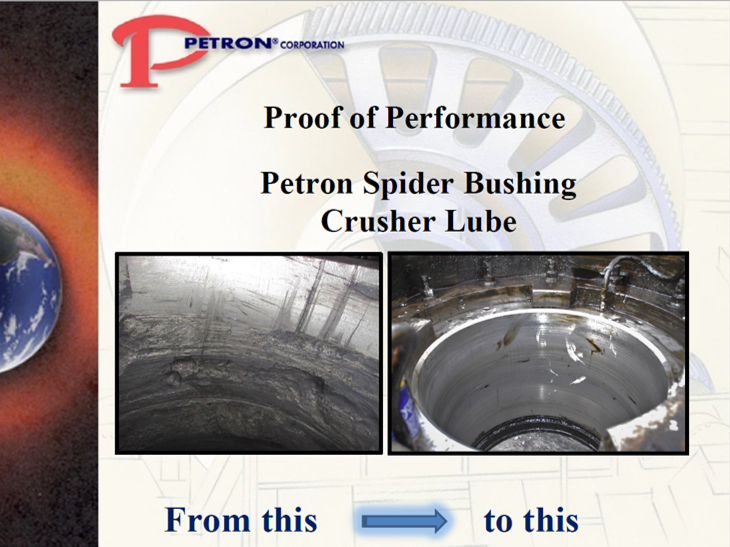

CASE STUDY: Savings of more than $150,000

using Petron Spider Bushing Crusher Lube

Heavy Duty Diesel Engine Oils

Triton ECT Diesel Engine Oil

This premium-quality, full-synthetic engine oil was developed for use in four-stroke cycle diesel engines operating under extreme temperature conditions. It meets API CK-4 performance requirements for use in modern low-emission engines designed to meet 2007 on-highway exhaust emission standards, and is backward serviceable for use in older diesel engines where API CI-4 PLUS oils are specified. It is specially formulated with advanced low-SAPS (sulfated ash, phosphorus and sulfur) additive technology to protect exhaust aftertreatment devices such as diesel particulate filters (DPFs) and diesel oxidation catalysts (DOCs). The full-synthetic formulation and SAE 5W-40 viscosity grade provide excellent low-temperature properties for better performance in harsh winter climates.

MEETS OR EXCEEDS

THE REQUIREMENTS OF:

- API Service CK-4

- API CI-4 PLUS

- Caterpillar ECF-3, ECF-2, ECF-1-a

- Cummins CES 20086

- Detroit Diesel DFS 93K222

- International (Navistar) diesel engines

- Mack EOS-4.5

- Volvo VDS-4.5

APPLICATIONS:

- On- and off-highway diesel equipment operating at low ambient temperatures

- On-highway diesel trucks equipped with exhaust aftertreatment devices such as diesel particulate filters and oxidation catalysts

- Diesel engines equipped with exhaust gas recirculation (EGR) or other NOx-reduction technologies

- Older diesel equipment with conventional, non-EGR engines and without after treatment devices

- Off-highway construction, earthmoving and mining equipment

- Mixed fleets with diesel- and gasoline-fueled vehicles

FEATURES/BENEFITS:

- Excellent protection for 2007emissions-compliant engines as well as older diesel engines

- Specially formulated to protect against particulate filter plugging and exhaust catalyst poisoning

- Outstanding soot control for protection against abrasive wear and soot-induced oil thickening

- Outstanding resistance to viscosity and thermal breakdown at high temperatures

- Protects against sludge and varnish formation

- Protects against wear, rust and bearing corrosion

- Excellent low-temperature pump ability for easier starting and less wear during cold starts

- High shear stability

- Good resistance to foaming and aeration

TRITON ARCTIC 0W-40 DIESEL ENGINE OIL

Phillips 66® Triton Arctic Diesel Engine Oil is a premium-quality, full-synthetic engine oil developed for use in four-stroke diesel engines operating under arctic temperature conditions. It meets API CK-4 performance requirements for use in modern low-emission engines designed to meet 2007 and later EPA on-highway exhaust emissions standards, and is backward-serviceable for use in older diesel engines. It is specially formulated for compatibility with exhaust-aftertreatment systems using diesel particulate filters (DPF), diesel oxidation catalysts (DOC) and/or selective catalytic reduction (SCR). The full-synthetic formulation and SAE 0W-40 viscosity grade provide excellent low-temperature properties for better performance in harsh arctic climates.

MEETS OR EXCEEDS

THE REQUIREMENTS OF:

- Diesel engines manufactured by Caterpillar, Cummins, Detroit Diesel, Mack, Mercedes-Benz, Volvo and other OEMs where the OEM specifies an SAE 0W-40, API CK-4engine oil

APPLICATIONS:

- On- and off-highway diesel equipment operating at low ambient temperatures

- On-highway diesel trucks equipped with exhaust-aftertreatment device s such as diesel particulate filters and oxidation catalysts

- Diesel engines equipped with exhaust gas recirculation (EGR) or other NOx-reduction technologies

- Older diesel equipment with conventional, non-EGR engines and without after treatment devices

- Off-highway construction, earthmoving and mining equipment

- Mixed fleets with diesel- and gasoline-fueled vehicles

FEATURES/BENEFITS:

- Excellent protection for newer low-emission diesel engines and older diesel engines

- Specially formulated to protect exhaust after treatment systems

- Outstanding soot control for protection against abrasive wear and soot-induced oil thickening

- Outstanding resistance to viscosity and thermal breakdown at high temperatures

- Exclusive Liquid Titanium® additive provides enhanced oxidation and wear control

- Protects against rust, bearing corrosion and wear

- Excellent low-temperature pumpability for easier starting and less wear during cold starts

- High shear stability

- High resistance to foaming and aeration

GUARDOL ECT®WITH LIQUID TITANIUM PROTECTION ADDITIVE

Guardol ECT (Emissions Compatible Technology) is a premium-quality, synthetic blend, API CK-4 engine oil with our exclusive Liquid Titanium protection additive. It is specially formulated to reduce wear and enhance protection against corrosion and oxidation, and approved under the latest OEM specifications from Caterpillar, Cummins, Detroit Diesel, Mack, Mercedes and Volvo. Guardol ECT is backward serviceable so older engines can get the benefits of our premium formulation with Liquid Titanium protection additive, which chemically bonds to metal surfaces to shield critical engine parts and provide enhanced protection against soot-induced oil thickening, lead-bearing corrosion, and oxidative and thermal oil breakdown. Guardol ECT with Liquid Titanium is designed for use in mixed fleets with both on-highway and off-road equipment operating in varying climates and under

MEETS OR EXCEEDS

THE REQUIREMENTS OF:

- ACEA E9

- API Service CK-4, CJ-4, CI-4 PLUS

- Caterpillar ECF-3, ECF-2, ECF-1-a

- Cummins CES 20086

- Detroit Diesel DFS 93K222

- Mack EOS-4.5

- MB-Approval 228.31 (SAE 15W-30 only)

- Volvo VDS-4.5

APPLICATIONS:

- On-highway diesel trucks equipped with exhaust aftertreatment devices

- Diesel engines equipped with exhaust gas recirculation (EGR) or other NOx-reduction technologies

- Older diesel equipment with conventional, non-EGR engines

- Off-highway construction, earthmoving and mining equipment

- Mixed fleets with diesel- and gasoline-fueled vehicles

FEATURES/BENEFITS:

- Proprietary additive package with exclusive titanium technology provides excellent wear, rust and bearing corrosion protection

- Advanced low-SAPS technology protects exhaust aftertreatment devices

- Exceptional soot control protects against abrasive wear and oil thickening

- Further enhances oxidation protection

- Resists viscosity and thermal breakdown, even at high temperatures

- Excellent low-temperature pumpability with soot-laden oil

- Excellent shear stability

- Resists foaming and aeration

- Protects against sludge and varnish formation

FLEET SUPREME EC®DIESEL ENGINE OIL

Fleet Supreme EC is compliant with the API CK-4 specification and was developed for use in four-stroke cycle diesel engines designed to meet 2007 on-highway exhaust emission standards. It also is backward serviceable for use in pre-2007 diesel engines where API CI-4 PLUS oils are specified.

MEETS OR EXCEEDS

THE REQUIREMENTS OF:

- ACEA E9

- API Service CK-4, CJ-4, CI-4 Plus, SN (SAE 15W-40 only)

- Caterpillar ECF-3, ECF-2, ECF-1-a

- Chrysler MS-10902 (SAE 15W-40)

- Cummins CES 20086

- Detroit Diesel DFS 93K222

- Ford WSS-M2C171-F1

- Mack EOS-4.5

- Mercedes-Benz Sheet 228.31 (SAE 15W-40)

- MTU MTL 5044 Type 2.1 (SAE 15W-40)

- Renault VI RLD-4

- Volvo VDS-4.5

APPLICATIONS:

- On-highway diesel trucks equipped with exhaust aftertreatment devices such as diesel particulate filters and oxidation catalysts

- Diesel engines equipped with EGR, ACERT or other emissions-control technologies

- Older diesel equipment with conventional, non-EGR engines

- Off-highway construction, earthmoving and mining equipment

FEATURES/BENEFITS:

- Excellent protection for new 2007emissions compliant engines and older diesel engines

- Specially formulated to protect exhaust after treatment devices

- Protects against particulate filter plugging

- Excellent soot control for protection against abrasive wear and soot-induced oil thickening

- Excellent resistance to viscosity and thermal breakdown at high temperatures

- Protects against sludge and varnish formation

- Protects against wear

- Protects against rust and bearing corrosion

- Good resistance to foaming and aeration

POWER-D®ENGINE OIL

Power-D Engine Oil is a premium-quality universal fleet engine oil designed for use in on-highway diesel trucks and off-highway diesel equipment, as well as in passenger cars and light trucks with either diesel or gasoline engines.

MEETS OR EXCEEDS

THE REQUIREMENTS OF:

- ACEA E7-04, E5-02, E3-96

- API Service CI-4 Plus (SAE 15W-30 only)

- Caterpillar ECF-2, ECF-1-a

- Cummins CES 20077, 20078

- Detroit Diesel DFS 93K214

- Global DHD-1

- Mack EO-N Premium Plus 03

- MAN 271, 3275

- Mercedes-Benz Sheet 228.3

- MTU MTL 5044 Type 2

- Renault VI RLD-2

- Volvo VDS-3

APPLICATIONS:

- On-highway diesel trucks equipped with EGR, ACERT or other technologies to meet 2004 and earlier exhaust emission standards

- Older diesel equipment with conventional, non-EGR engines

- Mixed fleets with both diesel- and gasoline-fueled vehicles

- Off-highway construction, earthmoving and mining equipment

- Farm equipment with

FEATURES/BENEFITS:

- Outstanding soot control for protection against abrasive wear and soot-induced oil thickening

- Outstanding resistance to viscosity and thermal breakdown at high temperatures

- Protects against sludge and varnish formation

- Excellent wear protection

- High shear stability

- Excellent rust and bearing corrosion protection

- Good low-temperature pumpability, even with soot-laden oil

- Good resistance to foaming and aeration

- Excellent protection for EGR-equipped engines, and extended drain capability for non-EGR diesel engines

Transmission Lubricants

SYNCON® FINAL DRIVE

Syncon Final Drive is a full-synthetic high-performance lubricant specially designed for use in the final drives and axles of Caterpillar off-highway equipment. It is formulated with advanced additive technology to provide improved gear and bearing life in final drives and axles. It meets the performance requirements of the Caterpillar FD-1 specification.

MEETS OR EXCEEDS

THE REQUIREMENTS OF:

- Caterpillar FD-11

FEATURES/BENEFITS:

- Improved bearing and gear life compared with TO-4 fluids

- Excellent oxidation resistance and thermal stability for long fluid life

- Protects against pitting, scuffing and wear

- Protects against rust and copper corrosion

- Compatible with a wide variety of seals

- Good foam resistance

Note: Follow Caterpillar recommendations for preferred viscosity grade and ambient temperature ranges. At very low ambient temperatures, warm-up is required prior to equipment operation.

POWERDRIVE®FLUID

PowerDrive Fluid is specifically formulated to meet Caterpillar’s TO-4 specification requirements. This high-quality lubricant is extremely shear stable and provides thorough protection against wear, oxidation, rust and corrosion to help you get more out of your CAT equipment as well as other equipment that requires an Allison C-4 type fluid.

OEM-APPROVED FOR SERVICE FILL IN:

- Allison TES-439 (SAE 30), for off-highway applications (Approval No. 439-33372012)

RECOMMENDED FOR SERVICE FILL IN:

- ZF torque converter transmissions in off-highway equipment where the OEM specifies a TE-ML 03C quality lubricant (SAE 10W-30)

MEETS OR EXCEEDS THE REQUIREMENTS OF:

- Caterpillar TO-4, TO-2 (obsolete specification)

- Vickers (Eaton) M-2950-S

FEATURES/BENEFITS:

- Powershift transmissions, hydrostatic transmissions, torque converters, final drives and hydraulic systems of Caterpillar, Euclid, Komatsu and other off-highway construction and mining equipment

- Heavy-duty automatic transmissions where the OEM specifies an Allison C-4 quality fluid

- Heavy-duty manual and semi-automatic transmissions in trucks and buses where the OEM specifies a Caterpillar TO-4 quality fluid or a heavy-duty engine oil

FEATURES/BENEFITS:

- Well-balanced frictional properties for smooth shifting and reduced brake chatter

- Excellent oxidation resistance and thermal stability for long fluid life

- Excellent wear protection for clutches, gears and hydraulic pumps

- High shear stability

- Protects against rust and corrosion

- Compatible with a wide variety of seals and friction materials

- Good low-temperature properties

- Good foam resistance

- High load-carrying capacity for protection of final drive gear sets

- Enhanced yellow metal protection from corrosion and deposits

POWERDRIVE FLUID 6000

PowerDrive Fluid 6000 (SAE 60) is formulated to the Caterpillar FD-1 specification for Final Drive and Axle Oil (FDAO). This advanced technology lubricant provides improved protection for gears and bearings in bevel gears and differentials.

MEETS OR EXCEEDS

THE REQUIREMENTS OF:

- Caterpillar FD-11

FEATURES/BENEFITS:

- Improved final drive performance compared to conventional TO-4 fluids

- Improved bearing life

- Extended gear life, proven improvements in pitting, wear and scuffing

- Superior wear protection under tough high-torque, low-speed operating conditions

- Excellent oxidation stability that reduces deposits and minimizes viscosity oxidative thickening throughout the drain cycle

- Reduced foaming tendencies; less foam results in lower wear rate in high-pressure contact zones

- Improved protection against rust and corrosion

Note: Follow Caterpillar recommendations for preferred viscosity grade and ambient temperature ranges. At very low ambient temperatures, warm-up is required prior to equipment operation.

POWERTRAN®FLUID

An amazingly versatile lubricant, PowerTran is designed for use in farm tractors and other off-highway equipment that utilizes a common fluid reservoir. A multifunctional fluid, it lubricates the transmission and final drive, actuates oil-wetted hydraulic disc brakes and serves as a hydraulic fluid to operate power-steering units, implements and attachments.

MEETS OR EXCEEDS THE REQUIREMENTS OF:

- AGCO (Deutz-Allis) Power Fluid 821XL

- AGCO (White Farm) Q-1826, Q-1802(Type 55 Fluid), Q-1766B

- Allison automatic transmissions in off-highway applications where a C-4 fluid is specified

- Case IH MS-1210, 1209, 1207, 1206

- Caterpillar TO-2 (obsolete)

- Case New Holland (CNH) MAT3525 (134-D Fluid)

- Denison Hydraulics HF-0, HF-1, HF-2

- John Deere J20C, J20D (low viscosity),J14C (Type 303 Fluid)

- Ford M2C134-D, M2C86-C&B, M2C41-B

- Ford-New Holland FNHA-2-C-201.00

- Kubota UDT Fluid

- Landini Tractor II Hydraulic Fluid

- Massey Ferguson M-1141, M-1135, M-1129A,CMS M-1145/M-1143

- Sundstrand Hydrostatic Transmission Fluid

- Vickers (Eaton) M-2950-S, I-286-S

- Volvo WB 101/VCE 1273.03

- ZF TE-ML 03E, 05F, 17E, 21F

- Meets API GL-4 performance requirements

FEATURES/BENEFITS:

- Excellent oxidation resistance and thermal stability

- Excellent wear protection for clutches, gears and hydraulic pumps

- Prevents brake chatter and grabbing

- Protects against rust and corrosion

- Excellent seal compatibility

- Outstanding foam resistance

- Suitable for year-round use inmost climates

POWERTRAN XP FLUID

PowerTran XP is a multifunctional fluid specially formulated for use in farm tractors and other off-highway equipment requiring one lubricant for the transmission, final drive, wet brakes and hydraulic systems. It meets the performance requirements of all major brands of farm tractors and other farm equipment that utilize a common fluid reservoir.

MEETS OR EXCEEDS

THE REQUIREMENTS OF:

- AGCO Power Fluid 821XL, Q-1826, Q-1802(Type 55 Fluid), Q-1766B

- Allison automatic transmissions in off-highway applications where a C-4 fluid is specified

- Case IH MS1210, MS1209, MS1207, MS1206

- Case New Holland (CNH) MAT3525 (134-DFluid), MAT3506, MAT3505, MAT 3540

- Denison Hydraulics HF-0, HF-1, HF-2

- Ford ESN-M2C134-D, ESN-M2C86-C, ESN-M2C86-B, ESN-M2C41-B

- Ford-New Holland FNHA-2-C-201.00

- John Deere JDM J20C, J14C(Type 303 Fluid)

- Kubota UDT Fluid, Super UDT 2

- Landini Tractor II Hydraulic Fluid

- Massey Ferguson CMS M1145/M1143,M1141, M1135, M1129A

- Sundstrand Hydrostatic Transmission Fluid

- Vickers (Eaton) M-2950-S, I-286-S

- Volvo VME WB 101 (VCE 1273.03)

- ZF TE-ML 03E, 05F, 17E, 21F

FEATURES/BENEFITS:

- Excellent oxidation resistance and thermal stability

- Excellent wear protection for clutches, gears and hydraulic pumps

- Prevents brake chatter and grabbing

- Protects against rust and corrosion

- Excellent seal compatibility

- Good foam resistance

- Improved shear stability

TRITON®HEAVY DUTY ATF

Formulated to offer better shear stability, oxidation control and wear protection, this full-synthetic ATF will go the extra mile in

your fleet applications.

OEM-APPROVED FOR SERVICE FILL IN:

- Allison automatic transmissions in off-highway applications where a C-4 fluid is specified

RECOMMENDED FOR SERVICE FILL IN:

- Allison automatic transmissions in on-highway applications where a TES-295quality fluid is specified

- Voith DIWA transmissions

- ZF Ecomat transmissions

FEATURES/BENEFITS:

- Excellent friction durability for smooth shifting throughout the service interval

- Outstanding oxidation resistance and thermal stability for long fluid life

- Protects against sludge and varnish formation

- Protects against wear

- High shear stability

- Protects against rust and corrosion

- Outstanding low-temperature properties for easier shifting in cold weather

- Good seal compatibility

- Good foam resistance

VERSATRANS® ATF

VersaTrans ATF is a premium-quality, synthetic-blend automatic transmission fluid specially designed for use in automatic transmissions in most passenger cars and light trucks. This versatile fluid helps reduce stocking multiple ATF products.

OEM-APPROVED FOR SERVICE FILL IN:

- Allison C-4

- Ford MERCON V

- Voith DIWA transmissions

Note: For questions about a specific application, please call our Technical Support Hotline.

MEETS OR EXCEEDS

THE REQUIREMENTS OF:

- •JASO M315, Class 1A

APPLICATIONS:

- Chrysler automatic transmissions, except continuously variable transmissions (CVTs)

- Ford automatic transmissions where MERCON V or an earlier-generation MERCON fluid (obsolete) is specified

- GM automatic transmissions in 2005 and earlier vehicles, except those that require DEXRON-VI for warranty coverage, or a CVT fluid

- Many import vehicles, including Acura, Audi, BMW, Honda, Hyundai, Infiniti, Kia, Mazda, Mercedes-Benz, Mitsubishi, Nissan, Porsche, Saab, Saturn, Toyota, Volkswagen and Volvo1

- Heavy-duty automatic and powershift transmissions in trucks and buses

- Hydraulic systems on industrial and mobile equipment operating over a wide temperature range

FEATURES/BENEFITS:

- Extensively field tested in a wide variety of domestic and import automatic transmissions

- Proper frictional properties for smooth shifting and excellent anti-shudder performance

- Excellent oxidation resistance and thermal stability for long fluid life

- Protects against sludge and varnish formation

- Protects against wear

- Protects against rust and corrosion

- Excellent low-temperature properties for easier shifting in cold weather

- Good seal compatibility

- Good foam resistance

VERSATRANS LV ATF

VersaTrans LV is the latest and greatest in ATF technology. This full-synthetic fluid is so advanced that it can offer protection and consistent shift performance for up to 100,000 miles in normal service.

OEM-APPROVED FOR SERVICE FILL IN:

- Allison automatic transmissions in off-highway applications where a C-4 fluid is specified

RECOMMENDED FOR SERVICE FILL IN:

- Allison automatic transmissions in on-highway applications where a TES-295quality fluid is specified

- Voith DIWA transmissions

- ZF Ecomat transmissions

APPLICATIONS:

- Heavy-duty automatic transmissions in trucks and buses in extended drain or severe service, such as in intracity transit buses, intercity tour coaches, school buses, emergency vehicles, recreational vehicles, refuse vehicles and commercial utility vehicles

FEATURES/BENEFITS:

- Excellent friction durability for smooth shifting throughout the service interval

- Outstanding oxidation resistance and thermal stability for long fluid life

- Protects against sludge and varnish formation

- Protects against wear

- High shear stability

- Protects against rust and corrosion

- Outstanding low-temperature properties for easier shifting in cold weather

- Good seal compatibility

SUPER ATF

Super ATF is a good choice for 2005 model year and older General Motors and Ford vehicles used in construction such as light-duty pickups and sport utility vehicles.

APPLICATIONS:

- Super ATF is recommended for service fill in GM and Ford automatic transmissions in2005 and earlier model year vehicles that are no longer under warranty and do not require a MERCON SP, MERCON V, Type F or Type T-IV fluid

- It also is recommended for use in import vehicles where the automaker specifies the same transmission fluid as used in GM vehicles for 2005 and earlier model years

- Recommended for Allison heavy-duty off-highway automatic transmissions that require a C-4 fluid

- Super ATF may be used in industrial and mobile hydraulic systems operating over a wide temperature range

- Super ATF is not recommended for use in automatic transmissions that require a GM DEXRON-VI or Ford MERCON V fluid for warranty coverage or in continuously variable transmissions (CVTs)

FEATURES/BENEFITS:

- Proper frictional properties for smooth shifting and excellent anti-shudder performance

- Excellent thermal stability and oxidation resistance for long fluid life

- Excellent low-temperature properties

- Protects against wear

- Minimizes sludge and varnish deposits

- Protects against rust and corrosion

- Good seal compatibility

- Suitable for both automotive and industrial applications

TRITON®SYNTHETIC TRANSOIL 50

When you need a transmission that can pass the test, trust Triton Synthetic Transoil 50. Triton Synthetic Transoil 50 is a full-synthetic SAE 50 transmission lubricant designed for use in heavy-duty truck and bus manual transmissions operating in extreme temperatures and/or extended service intervals.

MEETS OR EXCEEDS THE REQUIREMENTS OF:

- API Service GL-1, MT-1

- ArvinMeritor O-81

- Dana Spicer transmissions

- Eaton Fuller transmissions

- Eaton Roadranger E500 (PS-164 Rev 7)

- International TMS 6816

- Mack TO-A Plus

- MIL-L-2104D

- ZF-FreedomLine transmissions

APPLICATIONS:

- Recommended for use in ArvinMeritor, Dana Spicer, Eaton Fuller, International, Mack and other heavy-duty manual transmissions that require a non-EP gear oil (API GL-1/MT-1) or a MIL-L-2104D (APICD)quality engine oil

- Approved for 500,000-mile drain intervals in Eaton transmissions under the Eaton Roadranger PS-164 Rev 7 specification

FEATURES/BENEFITS:

- Extended-drain, all-season performance

- Outstanding oxidation resistance and thermal stability to minimize sludge and varnish formation

- Excellent low-temperature properties for easier shifting in cold weather

- High shear stability

- High load-carrying capacity

- Protects against component wear and gear micropitting

- Protects against rust and corrosion

- Good foam resistance

- Excellent seal compatibility

- Potential fuel-economy benefits compared with non-synthetic transmission fluids

TRITON SYNTHETIC MTF

Triton Synthetic MTF (Manual Transmission Fluid) is a full-synthetic, fuel-efficient transmission lubricant designed for use in heavy-duty, commercial manual transmissions operating in extreme temperatures and/or extended service intervals.

OEM-APPROVED FOR SERVICE FILL IN:

- Eaton PS-386 (supersedes Eaton PS-164 Rev 7)

MEETS OR EXCEEDS THE REQUIREMENTS OF:

- API Service MT-1

- Eaton Roadranger E500 PS-386 (SAE 40superseding PS-164)

- International (Navistar) TMS 6816

- Mack TO-A Plus

- Meritor O-81

- ZF-FreedomLine

FEATURES/BENEFITS:

- Extended drain, all-season performance

- Outstanding oxidation resistance and thermal stability to minimize sludge and varnish formation

- Improved low-temperature properties for easier shifting in cold weather

- Improved fuel efficiency

- High shear stability

- High load-carrying capacity

- Protects against component wear and gear micropitting

- Protects against rust and corrosion

- Good foam resistance

- Excellent seal compatibility

ENVIRONMENTALLY FRIENDLY PRODUCTS

POWERFLOW™ NZ HE HYDRAULIC OIL

Powerflow NZ HE Hydraulic Oil is a high-quality, high viscosity index, zinc-free antiwear hydraulic oil developed for use in mobile equipment operating over a wide temperature range. It is particularly recommended for use in off-road equipment manufactured by Hitachi, John Deere and others. It passes the visual “no sheen” requirements of the U.S. EPA Static Sheen Test, and is classified as inherently biodegradable by the OECD Test Method 301B.

MEETS OR EXCEEDS THE REQUIREMENTS OF:

- Bosch Rexroth RE 90220, Type HVLP

- DIN 51524 Part 3, Antiwear Hydraulic Oils, Type HVLP

- Eaton-Vickers M-2950-S, I-286-S

- German Steel Industry SEB 181222

- Hitachi Advanced Hydraulic Oil (for use in dry systems only) (ISO VG 46)

- ISO 11158:1997, Family H (Hydraulic Systems), Type HV

- Parker Hannifin (Denison) HF-0, HF-1, HF-2

- U.S. Steel 127

- U.S. EPA/U.S. Coast Guard Static Sheen Test, Federal Register Vol. 58, No. 41

APPLICATIONS:

- Off-road mobile construction and forestry equipment, such as backhoes, bulldozers, crawlers, excavators, skid-steer loaders and motor graders, where the manufacturer recommends a zinc-free hydraulic oil

- Hitachi construction equipment with 5,000-hour service intervals

- Industrial and mobile equipment operating in cold weather or in locations subject to wide temperature fluctuations

- Bucket trucks (cherry pickers) used for servicing electrical power lines

- Hydraulic hoists and service-station lifts

FEATURES/BENEFITS:

- High viscosity index to reduce internal oil leakage and increase hydraulic system efficiency by up to 6% compared to conventional single-grade hydraulic oils

- Excellent oxidation resistance and thermal stability

- Protects against rust and corrosion(reduced sludge and deposit formation)

- Excellent water-separating properties

- Excellent wear protection for hydraulic pumps and motors

- Improved product compatibility with traditional zinc-based products

- Good filterability

- Inherently biodegradable

- Nontoxic to aquatic organisms

- Suitable for year-round use

POWERFLOW NZ HYDRAULIC OIL

Powerflow NZ Hydraulic Oil1 is formulated with a zinc-free antiwear additive package to provide excellent wear protection for hydraulic pumps and motors, and to protect hydraulic system components against rust and corrosion. It has excellent oxidation resistance and thermal stability at high temperatures to minimize deposit formation and provide long service life. It has excellent water-separating properties to minimize the formation of emulsions, and is resistant to excessive foam buildup that can cause poor or sluggish hydraulic system response.

MEETS OR EXCEEDS THE REQUIREMENTS OF:

- Bosch Rexroth RE 90220, Type HLP

- DIN 51524 Part 2, Antiwear Hydraulic Oils, Type HLP

- Eaton-Vickers I-286-S, M-2950-S, 35VQ25A antiwear performance (brochure 03-401-2010 Rev 1 ISO 32, 46, and 68)

- Federal Register Vol. 58, No. 41, U.S. EPA/U.S. Coast Guard Static Sheen Test

- Fives Cincinnati P-68 (ISO VG 32), P-70 (ISO VG 46), P-69 (ISO VG 68) (approved)

- German Steel Industry SEB 181222

- ISO 11158:1997, Family H (Hydraulic Systems), Type HM

- Parker Hannifin (Denison) HF-0, HF-1, HF-2 (approved ISO 32, 46, and 68)

- U.S. Steel 127

APPLICATIONS:

- Hydraulic systems where the equipment manufacturer specifies a zinc-free antiwear hydraulic oil

- Hydraulic equipment used in environmentally sensitive areas, such as national parks, wildlife refuges, ski resorts and other recreational areas

- Hydraulic jacks and other equipment in machine shops

- Oil-drilling rigs and offshore platforms

- Marine cargo winches and steering systems

- Hydraulic hoists and service-station lifts

- Chain drives

- Electric motor bearings

FEATURES/BENEFITS:

- Excellent oxidation resistance and thermal stability

- Protects against rust and corrosion(reduced sludge and deposit formation)

- Excellent water-separating properties

- Excellent wear protection for hydraulic pumps and motors

- Improved product compatibility with traditional zinc-based products

- Outstanding air-release properties

- Inherently biodegradable

- Nontoxic to aquatic organisms

HYDRAULIC, R&O AND SPECIALTY OILS

POWERFLOW AW HYDRAULIC OIL

Powerflow AW Hydraulic Oil is a premium, zinc-based hydraulic fluid formulated for use in a wide variety of industrial and mobile hydraulic systems operating under high-pressure, high-temperature conditions. Powerflow AW Hydraulic Oil is available in four viscosity grades: ISO 32, 46, 68 and 100.

MEETS OR EXCEEDS THE REQUIREMENTS OF:

- Bosch Rexroth RE 90 220

- Denison Hydraulics HF-0, HF-1, HF-2

- DIN 51524 Part 2, Antiwear Hydraulic Oils, Type HLP

- German Steel Industry SEB 181222

- ISO 11158:1997, Family H (Hydraulic Systems), Type HM

- U.S. Steel 127

- Vickers (Eaton) M-2950-S, I-286-S

APPLICATIONS:

- Hydraulic systems of plastic injection- molding machines

- Automated machine tools

- Hydraulic elevators, hoists, presses and floor jacks

- Hydraulic systems on mobile construction equipment

- Marine cargo winches and steering systems

- Service-station lifts

- Air tools and other pneumatic equipment lubricated through air-line lubricators

- Moderately loaded, enclosed industrial gearboxes that do not require an extreme pressure (EP) gear oil (ISO VG 68, 100)

- Plain and rolling-element bearings in electric motors

FEATURES/BENEFITS:

- Outstanding performance in plastic injection-molding machines

- Excellent wear protection for hydraulic pumps and motors

- Protects against rust and corrosion

- Excellent water-separating properties

POWERFLOW HE HYDRAULIC OIL

Powerflow HE Hydraulic Oil is a premium- quality, high viscosity index, antiwear hydraulic oil developed for use in industrial and mobile equipment operating in cold climates or in locations subject to wide variations in ambient temperatures. Powerflow HE Hydraulic Oil is available in three viscosity grades: ISO 32, 46 and 68.

MEETS OR EXCEEDS THE REQUIREMENTS OF:

- DIN 51524 Part 3, Anti-Wear Hydraulic Oils, Type HVLP

- Eaton-Vickers M-2950-S, I-286-S

- ISO 11158:1997, Family H (Hydraulic Systems), Type HV

- Parker Hannifin (Denison) HF-0, HF-1, HF-2

APPLICATIONS:

- Industrial and mobile equipment operating in cold weather or in locations subject to wide temperature fluctuations

- Bucket trucks (cherry pickers) used for servicing electrical power lines or for tree-trimming

- Hydraulic hoists and service-station lifts

- Marine cargo winches and steering systems

- Off-road construction, mining and marine equipment

- Chain drives

- Electric motor bearings

FEATURES/BENEFITS:

- High viscosity index to reduce internal oil leakage and increase hydraulic system efficiency by up to 6% compared to conventional single-grade hydraulic fluids

- Excellent service over a wide temperature range

- Excellent wear protection for hydraulic pumps and motors

- Excellent oxidation resistance and thermal stability

- Protects against rust and corrosion

- Excellent water-separating properties

- Good foam resistance

- Excellent low-temperature properties for cold start-ups

- High dielectric strength for use in electrical- service bucket trucks (cherry pickers)2

ROCK DRILL OIL

Rock Drill Oil is an adhesive, extreme pressure lubricant specially developed for use in pneumatic equipment such as rock drills, jackhammers and pavement breakers.

MEETS OR EXCEEDS THE REQUIREMENTS OF:

- Gardner-Denver Rock Drill Oil

- Ingersoll-Rand Rock Drill Oil

APPLICATIONS:

- Rock Drill Oil is recommended for use in pneumatic equipment manufactured by leading OEMs, including Chicago Pneumatic, Gardner-Denver, Ingersoll-Rand and Joy; typical applications include drifters, jackhammers, pavement breakers, rock drills and stoppers

- Rock Drill Oil also is recommended for the lubrication of slideways on machine tools such as boring machines, grinders, milling machines and planers

FEATURES/BENEFITS:

- Excellent extreme pressure properties

- Protects against wear and seizure

- Good adhesiveness to metal surfaces in the presence of moisture

- Good oxidation resistance and thermal stability

- Protects against rust and corrosion

- Low odor

- Good foam resistance

- Seven viscosity grades for use over a wide range of temperatures

MEGAFLOW® AW HYDRAULIC OIL

Megaflow AW Hydraulic Oil was developed for use in a wide variety of industrial, mobile and marine hydraulic system applications. It is recommended for use in all types of high-speed, high-pressure hydraulic pumps. Megaflow AW Hydraulic Oil is available in eight viscosity grades: ISO 22, 32, 46, 68, 100, 150, 220 and 320. It is formulated with high-quality paraffinic base oils, a zinc dithiophosphate antiwear additive, rust and oxidation inhibitors, and an antifoam agent.

MEETS OR EXCEEDS

THE REQUIREMENTS OF:

•Bosch Rexroth RE 90 220

•Denison Hydraulics HF-0, HF-1, HF-2

• DIN 51524 Part 2, Antiwear Hydraulic Oils,Type HLP

•German Steel Industry SEB 181222

• ISO 11158:1997, Family H (HydraulicSystems), Type HM

•U.S. Steel 127

•Vickers (Eaton) M-2950-S, I-286-S

APPLICATIONS:

- Hydraulic systems on industrial, mobile and marine equipment

- Automated machine tools

- Elevators, hoists, presses and floor jacks

- Marine cargo winches and steering systems

- Mobile construction equipment

- Plastic injection-molding machines

- Service-station lifts

- Air tools and other pneumatic equipment lubricated through air-line lubricators

- Chain drives

•Electric motor bearings

• Moderately loaded, enclosed industrial gearboxes that do not require an extreme pressure (EP) gear oil

FEATURES/BENEFITS:

- Excellent wear protection for hydraulic pumps and motors

- Excellent oxidation resistance and thermal stability

- Protects against rust and corrosion

- Excellent water-separating properties

- Excellent filterability, even in the presence of a small amount of water

- Good foam resistance

MEGAFLOW AW HVI HYDRAULIC OIL

Megaflow AW HVI Hydraulic Oil is a high-quality, high viscosity index, anti-wear hydraulic oil developed for use in industrial and mobile equipment operating in cold climates or in locations subject to wide variations in ambient temperatures. It meets the performance requirements of all major hydraulic pump manufacturers, and is recommended for use in all types of high-pressure, high-speed hydraulic pumps. Megaflow AW HVI Hydraulic Oil is available in six viscosity grades: ISO 15, 22, 32, 46, 68 and 100.

MEETS OR EXCEEDS THE REQUIREMENTS OF:

- Bosch Rexroth RE 90 220

- Denison Hydraulics HF-0, HF-1, HF-2

- DIN 51524 Part 2, Antiwear Hydraulic Oils,Type HLP

- German Steel Industry SEB 181222• ISO 11158:1997, Family H (HydraulicSystems), Type HM

- U.S. Steel 127

- Vickers (Eaton) M-2950-S, I-286-S

APPLICATIONS:

- Hydraulic systems on industrial, mobile and marine equipment

- Automated machine tools

- Elevators, hoists, presses and floor jacks

- Marine cargo winches and steering systems

- Mobile construction equipment

- Plastic injection-molding machines

- Service-station lifts

- Air tools and other pneumatic equipment lubricated through air-line lubricators

- Chain drives

- Electric motor bearings

- Moderately loaded enclosed industrial gearboxes that do not require an extreme pressure (EP) gear oil

FEATURES/BENEFITS:

- Excellent wear protection for hydraulic pumps and motors

- Excellent oxidation resistance and thermal stability

- Protects against rust and corrosion

- Excellent water-separating properties

- Excellent filterability, even in the presence of a small amount of water

- Good foam resistance

TURBINE OIL

Turbine Oil is a high-quality rust- and oxidation-inhibited turbine oil formulated with hydrocracked base stocks and select additives for use in steam and hydroelectric turbines, rotary air compressors and other industrial applications.

MEETS OR EXCEEDS THE REQUIREMENTS OF:

- ABB G12106

- Alstom Power HTGD 90 117, for turbines without gear drives

- Ansaldo Energia AE94.3A & AE94.2 without gear drives (ISO VG 46) (approved)

- ANSI/AGMA Standard 9005-E02, R&O Inhibited Oils

- ASTM D4304-06a, Type I Turbine Oil

- British Standard 489

- China National Standard GB 11120-2011L-TSA (ISO VG 32 & 68) (approved)

- Denison Hydraulics HF-1

- DIN 51515 Part 1, Lubricating Oils, Type L-TD

- DIN 51517 Part 2, Lubricating Oils, Type CL

- DIN 51524 Part 1, Hydraulic Oils, Type HL

- General Electric GEK 46506e, GEK 32568k, GEK 27070 (obsolete), GEK 28143b (obsolete), GEK 120498 (obsolete)

- MHI MA04-MA-CL001 & MA04-MA-CL002

• Siemens Power Generation TLV 9013 04,TLV 9013 05

• U.S. Military MIL-PRF-17672D, Symbol 2075T-H (ISO VG 32), 2110 T-H (ISO VG 46), 2135T-H (ISO VG 68)

• U.S. Steel 126

APPLICATIONS:

- Direct-drive steam turbines and hydroelectric turbines

- Air tools and other pneumatic equipment lubricated through air-line lubricators

- Centrifugal and rotary air compressors

- Lightly loaded enclosed gear drives where the OEM specifies an R&O type oil(ISO VG 68, 100)

- Electric motor bearings, fan bearings and blower bearings

- Vacuum pumps, deep-well water pumps and machine tools

FEATURES/BENEFITS:

- Excellent oxidation resistance and thermal stability for long service life

- Protects against sludge and varnish formation

- Protects against rust and corrosion

- Excellent water-separating properties

- Low carbon-forming tendency for use in air compressors

- Good foam resistance

SYNDUSTRIAL®HYDRAULIC 100

Syndustrial Hydraulic 1001 is a premium- quality, readily biodegradable, synthetic, fire-resistant hydraulic fluid developed for use in hydraulic systems operating in areas subject to fire hazards, such as in underground mining operations, steel mills and foundries.

APPLICATIONS:

- Hydraulic systems subject to fire hazards and extreme heat

- Replacement for petroleum-based antiwear hydraulic fluids

- Steel mills, surface mines, foundries and manufacturing plants

FEATURES/BENEFITS:

- Fire-resistant

- High flash point, fire point and autoignition temperature for reduced fire/explosion hazard

- Outstanding oxidation resistance and thermal stability at high temperatures

- Good low-temperature fluidity

- Excellent load-carrying capacity

- Protects against rust and corrosion

- Nontoxic, non-irritating and contains no hazardous ingredients

- Readily biodegradable

- Fire resistance certified by Factory Mutual Research Corporation

- MSHA-approved

1 Note: Syndustrial Hydraulic 100 should not be mixed with conventional antiwear hydraulic oils, invert emulsions, phosphate esters or water-glycol fluids. It is a stand-alone product and cannot be used as top-up for existing hydraulic systems with different fluid types. For information on seal and elastomer compatibility, please call our Technical Support Hotline.

MULTIPURPOSE R&O OIL

Multipurpose R&O Oil is a rust- and oxidation-inhibited industrial oil fortified with an ashless antiwear additive package.

MEETS OR EXCEEDS THE REQUIREMENTS OF:

•ABB G12106

•AGMA R&O Grades 0 through 7 (non-EP)

•Alstom HTGD 90117 for geared turbines

• ASTM D4304 Type I Turbine Oil(ISO VG 32, 46, 68, 100)

• British Standard 489-1999

• Cincinnati Lamb Machine SpecificationsP-38 (ISO VG 32), P-55 (ISO VG 46), P-54(ISO VG 68), P-57 (ISO VG 150)

• Denison Hydraulics HF-1

• DIN 51517 Part 1, Lubricating Oils, Type CL

• DIN 51524 Part 1, R&O Hydraulic Oils, Type HL

• General Electric GEK-101941a, GEK-46506d and obsolete GEK-27070,GEK-28143a

• Ingersoll-Rand Centakcentrifugal compressors

•Mitsubishi Type 2 Multipurpose R&O Oil

•Solar ES9-224 Class II Turbine Oil

•Toshiba

•U.S. Military Specification MIL-L-17672D

•U.S. Steel 126, R&O Inhibited Hydraulic Oil

APPLICATIONS:

- Air tools and other pneumatic equipment lubricated through air-line lubricators

- Centrifugal air compressors

- Crankcases of sealed hydraulic pumps

- Direct-drive, geared-steam and hydroelectric turbines

- Industrial gearboxes with spur, helical and double-helical gears that do not require an extreme pressure (EP) gear oil

- Lightly loaded plain and rolling-element bearings, such as those in electric motors and blowers

- Vacuum pumps, deep-well water pumps and machine tools

- General-purpose plant lubrication

FEATURES/BENEFITS:

- Good oxidation resistance to minimize sludge and varnish formation

- Protects against wear

- Protects against rust and corrosion

- Excellent water-separating properties

- Low carbon-forming tendency for use in air compressors

- Good foam resistance

- Available in eight viscosity grades for use in many applications over a wide temperature range

SYNCON®R&O OIL

Syncon Synthetic R&O Oil comprises a line of synthetic PAO-based, multifunctional products intended for industrial applications.

APPLICATIONS:

- Rotary air compressors where the manufacturer specifies a PAO-based lubricant2

- Plain and rolling-element bearings operating at very high or very low temperatures

- Lightly to moderately loaded, enclosed industrial gearboxes that do not require an extreme pressure (EP) gear lubricant

- Industrial worm-gear drives with bronze-on-steel gears

- Circulating systems of paper-machine dryer sections and calender stacks

- Industrial equipment operating over a wide temperature range where inhibited mineral oil is recommended

Note: Always follow the equipment manufacturer’s recommendations for selecting the proper viscosity grade and for preferences regarding the use of PAO-based lubricants. For information on compatibility with seals, paints and plastics, please call our Technical Support Hotline.

T5X OFF-ROAD

T5X Off-Road Mobile Hydraulic Fluid is a high-performance hydraulic fluid designed primarily for use in the hydraulic systems of Caterpillar and other off-highway mobile equipment. It also may be used in the hydrostatic transmissions of some off-road equipment. Available in 10W.

APPLICATIONS:

- Hydraulic systems and some hydrostatic transmissions on Caterpillar and other off-

highway mobile equipment - Hydraulic systems operating over a widetemperature range

FEATURES/BENEFITS:

- High viscosity index for use over a wide temperature range

- Excellent wear protection for hydraulic system components

- High dispersancy-detergency for excellent system cleanliness

- Protects against deposit formation

- Protects against rust and corrosion

- Good resistance to foaming

POWERDRIVE FLUID 10W

PowerDrive Fluid is a high-performance multi-functional fluid developed for use in transmissions, final drives and hydraulic systems of off-highway equipment where a fluid meeting Caterpillar TO-4 performance requirements is specified. It provides substantially improved friction and antiwear performance compared with older API CD/TO-2 quality fluids, resulting in longer equipment life and reduced risk of field failure. The 10W viscosity grade is also recommended for use in Allison off-highway heavy-duty automatic transmissions where a C-4 quality fluid is specified.

APPLICATIONS:

- Powershift transmissions, hydrostatic transmissions, torque converters, final drives and hydraulic systems of Caterpillar, Euclid, Komatsu and other off-highway construction and mining equipment

- Heavy-duty automatic transmissions where the OEM specifies an Allison C-4 quality

FEATURES/BENEFITS:

- Well-balanced frictional properties for efficient clutch operation and improved wet brake performance

- Excellent oxidation resistance and thermal stability for long fluid life

- High load-carrying capacity for protection of final drive gear sets

- Excellent deposit control and wear protection

- Protects yellow metals against corrosion

- High shear stability

- Compatible with a wide variety of seals and friction materials

- Good low-temperature properties

- Good foam resistance

POWERDRIVE SYNTHETIC ALL SEASON TO-4 FLUID

PowerDrive Synthetic All Season TO-4 Fluid is a premium quality, synthetic, multi-functional fluid developed for use in transmissions, final drives and hydraulic systems of off-highway equipment where a fluid meeting Caterpillar TO-4 performance requirements is specified. It is a multigrade fluid particularly recommended for equipment operating in very cold temperatures as well as year-round service in most climates. Available in 5W-30.

APPLICATIONS:

- Powershift transmissions, hydrostatic transmissions, torque converters, final drives and hydraulic systems of Caterpillar, Euclid, Komatsu and other off-highway construction and mining equipment

- Heavy-duty automatic transmissions where the OEM specifies an Allison C-4quality fluid

- Heavy-duty manual and semi-automatic transmissions in trucks and buses where the OEM specifies a Caterpillar TO-4 quality fluid or a heavy-duty engine oil

FEATURES/BENEFITS:

- Synthetic formulation for enhanced performance in arctic temperatures

- Well-balanced frictional properties for smooth and efficient clutch operation

- Outstanding oxidation resistance and thermal stability for long fluid life

- High load-carrying capacity for protection of final drive gear sets

- Excellent deposit control and wear protection

- Protects yellow metals against corrosion

- High shear stability

- Compatible with a wide variety of seals and friction materials

- Excellent low-temperature properties for easier starting at low ambient temperatures

- Good foam resistance

- Suitable for year-round use inmost climates

POWERDRIVE SYNTHETIC ARCTIC TO-4 FLUID

PowerDrive Synthetic Arctic TO-4 Fluid is a premium quality, synthetic, multigrade fluid specially developed for use in off-highway equipment operating in arctic climates where a fluid meeting Caterpillar TO-4 performance requirements is specified. It is a multi-functional fluid for use in transmissions, final drives, hydraulic systems and wet brakes. It is not for use in engines. Available in 0W-20.

APPLICATIONS:

• Powershift transmissions, hydrostatic transmissions, torque converters, final drives and hydraulic systems of Caterpillar,

Euclid, Komatsu and other off-highway

construction and mining equipment

operating in arctic climates

FEATURES/BENEFITS:

- Synthetic formulation for enhanced performance in arctic temperatures

- Well-balanced frictional properties for smooth and efficient clutch operation

- Outstanding oxidation resistance and thermal stability for long fluid life

- High load-carrying capacity for protection of final drive gear sets

- Excellent deposit control and wear protection

- Protects yellow metals against corrosion

- High shear stability

- Compatible with a wide variety of seals and friction materials

- Excellent low-temperature properties for easier starting at low ambient temperatures

- Good foam resistance

CAUTION: Refer to the OEM recommendations for recommended temperature ranges.

GEAR OILS

EXTRA DUTY GEAR OIL

Extra Duty Gear Oil is a heavy-duty, extreme pressure (EP) industrial gear oil developed for use in enclosed gearboxes operating under moderate to severe service conditions.

MEETS OR EXCEEDS THE REQUIREMENTS OF:

- AGMA Standard 9005-E02 (formerly 250.04)

- Aluminum Company of America (ALCOA)

- Cincinnati Machine Specifications P-63 (2 EP), P-76 (3 EP), P-77 (4 EP), P-74 (5 EP), P-59 (6 EP), P-35 (7 EP), P-78 (8A EP)

- DIN 51517 Part 3, Lubricating Oils, Type CLP

- German Steel Industry Specification SEB 181226, Type CLP

- ISO 12925-1:1996, Type L-CKC

- U.S. Steel 224

- Most major gearbox manufacturers, including Amarillo, David Brown, Falk, Hansen and Lufkin

APPLICATIONS:

- Enclosed industrial gear sets operating under heavy loads, high peak loads or intermittent shock loads

- Enclosed spur, bevel, helical, herringbone and planetary gear sets where the equipment manufacturer specifies an AGMA EP gear oil

- Heavily loaded plain and rolling-

element bearings

FEATURES/BENEFITS:

- High load-carrying capacity for protection against scuffing and wear

- Good oxidation resistance and

thermal stability - Protects against deposits and

varnish formation - Protects against rust and corrosion

- Fast water separation

- Quick foam release

GLW

GLW 220, 320 and 460 are premium-quality, extreme pressure, longwall mining gear lubricants specifically developed for the lubrication of gearboxes of Joy Machinery mining equipment and other mining and construction equipment operating under extreme loads and in a heavily contaminated, wet environment.

MEETS OR EXCEEDS THE REQUIREMENTS OF:

- ANSI/AGMA Standard 9005-E02

- DIN 51517 Part 3, Type CLP

- U.S. Steel 224

- Joy Mining Machinery specifications

TO-MEP (ISO VG 220), TO-HEP (ISO VG 320), TO-HD (ISO VG 460)

APPLICATIONS:

- Enclosed gearboxes of longwall mining machinery and heavy construction and excavation equipment

- Enclosed industrial gearboxes operating in the presence of water, such as in steel mills and rock quarries

- Gear drives and pinion stands of metal-rolling mills, ball mills and cement mills

FEATURES/BENEFITS:

- Excellent performance in wet or contaminated gearboxes

- Outstanding load-carrying capacity

- Excellent protection against scuffing

and wear - Good oxidation resistance and

thermal stability - Good deposit control

- Protects against rust and corrosion

- Good seal compatibility

- Chlorine-free for reduced

environmental impact

SYNCON® PREMIUM EP GEAR OIL

Syncon Premium EP Gear Oil is a premium-quality, synthetic, extreme pressure gear lubricant specially formulated to protect the heavily loaded enclosed gears and bearings found in General Electric wheel motors in mining haul trucks. It also is recommended for use in enclosed industrial gearboxes operating under extreme temperature conditions.

MEETS OR EXCEEDS THE REQUIREMENTS OF:

- AGMA 9005-E02 (formerly 250.04)

- Cincinnati Lamb Machine Specifications, P-74 (ISO VG 220), P-59 (ISO VG 320) and P-35 (ISO VG 460)

- DIN 51517 Part 3, Lubricating Oils,

Type CLP HC - German Steel Industry Specification

SEB 181226, Type CLP HC - ISO 12925-1:1996, Type L-CKC

- Joy Machinery Specifications TO-SHEP (ISO VG 320), TO-SMEP (ISO VG 220)

- U.S. Steel 224

- Most major gearbox manufacturers, including Amarillo, David Brown, Falk, Hansen and Lufkin

APPLICATIONS:

- Heavily loaded enclosed gearboxes, such as those commonly found in mine hoists and mining machinery

- Enclosed industrial gearboxes operating at very low or very high temperatures, or operating continuously at higher-than-normal operating temperatures

- Heavily loaded plain and

rolling-element bearings operating

under extreme temperatures - Applications where the equipment manufacturer recommends a high viscosity index synthetic EP gear oil

FEATURES/BENEFITS:

- Outstanding oxidation resistance and thermal stability at high temperatures

- Outstanding low-temperature properties

- High viscosity index and low pour point for use over a wide temperature range

- Excellent extreme pressure properties

- Protects against scuffing and wear

- Protects against rust and corrosion

- Non-chlorinated additive system

- Suitable for year-round use

- Extended service intervals compared with conventional mineral oil-based gear oils

SYNCON® EP PLUS GEAR OIL

Syncon EP Plus Gear Oil is a premium-quality, high viscosity index, synthetic, extreme pressure gear lubricant recommended for heavily loaded bearings and enclosed gears operating under extreme temperature conditions.

MEETS OR EXCEEDS THE REQUIREMENTS OF:

- ANSI/AGMA Standard 9005-F16,Anti-Scuff Lubricants (AS)

- DIN 51517 Part 3, Lubricating Oils, Type CLP HC

- German Steel Industry SEB 181226,Type CLP HC

- ISO 12925-1:1996, Type L-CKC

•Joy Machinery Specification TO-SHEP(ISO VG 320), TO-SMEP (ISO VG 220) - U.S. Steel 224

APPLICATIONS:

- Heavily loaded enclosed gear drives, such as those found in mine hoists and mining machinery

- Enclosed industrial gear drives operating at very low or very high temperatures, or operating continuously at higher than normal operating temperatures

- Heavily loaded plain and rolling-element bearings operating at extreme temperatures

- Applications where the equipment manufacturer recommends a high VI,

synthetic, extreme-pressure gear oil

FEATURES/BENEFITS:

- Outstanding oxidation resistance and thermal stability at high temperatures

•Outstanding low-temperature properties - High viscosity index and low pour point for use over wide temperatures

- Excellent extreme-pressure properties

- Protection against scuffing and wear

- Protects against rust, corrosion, and foaming

- Non-chlorinated additive system

•Suitable for year-round use

•Extended service intervals compared to mineral oil-based gear oils

GEAR SHIELD

Gear Shield is a high-viscosity fluid that provides superior separation of gear teeth in the heaviest loaded zone of gear-tooth mesh. Gear Shield is a blend of high-viscosity base fluids and highly refined resins combined with extreme pressure (EP) and oxidation-resistant additives, further enhancing this protection. Gear Shield is the open-gear lubricant of choice for mills and kilns in mineral processing such as gold, copper, iron, taconite and phosphate. It is also the product of choice in the power generation and cement industries.

MEETS OR EXCEEDS THE REQUIREMENTS OF:

- Exceeds OEM and AGMA base oil viscosity requirements for open gear lubricants applied by intermittent spray application

APPLICATIONS:

- Gear Shield NC is recommended for use in gear operating temperatures up to the flashpoint of the product; it can be applied by spraying, brushing or dripping and is designed to be applied through all automatic lubrication equipment

FEATURES/BENEFITS:

- High-viscosity fluid designed to lubricate heavily loaded open gears

- Antiwear and extreme pressure additives provide unparalleled protection in the most heavily loaded zones of gear-tooth mesh

- Industry-leading FZG Specific Mass Loss wear test result (0.0532 mg/kWh)

- No build-up in gear-tooth roots

- Pumps freely down to 32ºF/0ºC; for applications below 32°F/0°C, use Gear Shield NCW

- Environmentally safe; passes TCLP Protocol A; does not contain chlorinated solvents or lead and is free of all carcinogens

OPEN GEAR LUBE

Open Gear Lube is a viscous, semifluid lubricant designed to lubricate open gears on shovels, draglines and associated mining equipment under all conditions. Open Gear Lube is designed to be applied through all automatic lubrication equipment. Open Gear Lube does not contain chlorinated solvents.

MEETS OR EXCEEDS THE REQUIREMENTS OF:

- • Open Gear Lube exceeds OEM base oilviscosity requirements for open gearlubricants on shovels and draglines

APPLICATIONS:

- Open Gear Lube is designed to lubricate open gears on shovels, draglines and associated mining equipment under all conditions; it can be applied by spraying, brushing or dripping andis designed to be applied through all automatic lubrication equipment

FEATURES/BENEFITS:

- High-viscosity fluid designed to lubricate heavily loaded open gears and extend component life while reducing Open GearLube consumption

- Solid and organo-metallic antiwear and extreme pressure additives provide protection in heavily loaded zones of gear-tooth mesh

- Open Gear Lube 595 NC is recommended for use in ambient temperatures ranging from 32°F (0°C) and above; for applications below 32°F (0°C), use Open Gear Lube 585 NC or 585 NCW

- Lubricant resists wash-off in rain and snow

- Environmentally safe; no chlorinated solvents, lead or carcinogens

Greases

DYNALIFE® CG (NLGI #0.5/1)

Dynalife CG is a high performance, polymer-containing, extreme pressure (EP) lithium grease developed for use in grease-lubricated flexible couplings, such as those commonly found in mining equipment, power plants, manufacturing plants and chemical plants.

It has exceptional resistance to oil separation when subjected to the high centrifugal forces typically encountered with medium- and high-speed gear, metallic grid and chain couplings.

MEETS OR EXCEEDS THE REQUIREMENTS OF:

- ANSI/AGMA Standard 9001-B97, Type CG-1 &CG-2 for medium- and high-speed couplings

APPLICATIONS:

- Gear, metallic grid and flexible chain couplings

- Couplings commonly used in mining and gas-field equipment

- Couplings and universal joints operating under high centrifugal forces

- Couplings used between electric motors and gearboxes in industrial and chemical plants

FEATURES/BENEFITS:

- Outstanding resistance to oil separation

- Excellent oxidation resistance and thermal stability

- High load-carrying capacity

- Protects against rust and corrosion

- Minimizes friction and wear to help extend coupling life

OPEN GEAR LUBE

Open Gear Lube is a viscous, semifluid lubricant designed to lubricate open gears on shovels, draglines and associated mining equipment under all conditions. Open Gear Lube is designed to be applied through all automatic lubrication equipment. Open Gear Lube does not contain chlorinated solvents.

MEETS OR EXCEEDS THE REQUIREMENTS OF:

- • Open Gear Lube exceeds OEM base oilviscosity requirements for open gearlubricants on shovels and draglines

APPLICATIONS:

- Open Gear Lube is designed to lubricate open gears on shovels, draglines and associated mining equipment under all conditions; it can be applied by spraying, brushing or dripping andis designed to be applied through all automatic lubrication equipment

FEATURES/BENEFITS:

- High-viscosity fluid designed to lubricate heavily loaded open gears and extend component life while reducing Open GearLube consumption

- Solid and organo-metallic antiwear and extreme pressure additives provide protection in heavily loaded zones of gear-tooth mesh

- Open Gear Lube 595 NC is recommended for use in ambient temperatures ranging from 32°F (0°C) and above; for applications below 32°F (0°C), use Open Gear Lube 585 NC or 585 NCW

- Lubricant resists wash-off in rain and snow

- Environmentally safe; no chlorinated solvents, lead or carcinogens

MULTIPLEX® 220 (NLGI #1 & #2)

Multiplex 220 is manufactured with high-quality base oils, a special polymer, and a lithium complex soap thickener. It is fortified with EP and antiwear additives, a tackifier, and rust and oxidation inhibitors to provide outstanding wear protection, excellent thermal stability at high temperatures, and excellent resistance to corrosion and water washout. It forms an effective seal to help minimize bearing contamination and provides a high level of adhesion to bearing surfaces for improved retention and reduced leakage.

MEETS OR EXCEEDS THE REQUIREMENTS OF:

- NLGI GC-LB-certified for use as a multipurpose automotive wheel bearing and chassis lubricant

APPLICATIONS:

- Wheel bearings of passenger cars, trucks, high-performance vehicles, sport utility vehicles and motorcycles, particularly those equipped with disc brakes

- Ball joints, universal joints, other chassis parts, and water pumps on passenger cars, trucks and other mobile equipment

- Heavily loaded plain and rolling-

element bearings in industrial, mining and mobile equipment

FEATURES/BENEFITS:

- Excellent high temperature performance

- Outstanding wear protection

- Good load-carrying capacity

- Excellent resistance to water washout

- Protects against rust and corrosion

- Excellent low temperature pumpability

- NLGI GC-LB-certified

MULTIPLEX 600 (NLGI #1 & #2)

Multiplex 600 is manufactured with high-quality base oils, a special polymer and a lithium complex soap thickener. It is fortified with EP and antiwear additives plus rust and oxidation inhibitors. It has excellent thermal stability at high temperatures, high load-carrying capacity for excellent wear protection, and protects metal parts against rust and corrosion. Its tackiness properties and heavy base oil provide a high level of adhesion to bearing surfaces, maintaining an effective seal to help minimize bearing contamination, improve retention, reduce leakage and provide excellent resistance to water washout.

MEETS OR EXCEEDS THE REQUIREMENTS OF:

- NLGI GC-LB-certified for use as a multipurpose automotive wheel bearing and chassis lubricant

APPLICATIONS:

- Agricultural, construction, mining and industrial equipment operating under heavy or shock loads

- Wheel bearings of passenger cars, trucks, high-performance vehicles, sport utility vehicles and motorcycles equipped with disc brakes

- Conveyor bearings

- Ball joints, universal joints, other chassis parts, and water pumps on passenger cars, trucks and other mobile equipment

- Pellet mills manufactured by Bliss Industries(Grade No. 2)

FEATURES/BENEFITS:

- Excellent high temperature performance

- Excellent wear protection

- High load-carrying capacity

- Protects against rust and corrosion

- Excellent resistance to water washout

- Good low temperature pumpability

- NLGI GC-LB-certified

MULTIPLEX®FS 100 (NLGI #2)/220 (NLGI #2)/460 (NLGI #1.5)

Multiplex FS is manufactured with a synthetic polyalphaolefin (PAO) base oil and a lithium complex soap thickener. It is fortified with EP and antiwear additives plus rust and oxidation inhibitors to provide excellent wear protection, corrosion resistance and long service life. It has outstanding thermal stability at high temperatures and outstanding pumpability at low temperatures for use over a wide temperature range.

MEETS OR EXCEEDS THE REQUIREMENTS OF:

- Multiplex FS 220 is NLGI GC-LB-certified for use as a multipurpose automotive wheel bearing and chassis lubricant

APPLICATIONS:

- Chassis parts and wheel bearings on passenger cars, trucks and other mobile equipment

- Moderately to heavily loaded plain and rolling-element bearings in industrial, mining, marine and mobile off-highway equipment

- Heavily loaded plain and rolling-element bearings in industrial, mining, marine and mobile off-highway equipment

FEATURES/BENEFITS:

- Outstanding oxidation resistance and thermal stability at high temperatures

- Outstanding pumpability at low temperatures

- Excellent wear protection for longer equipment life

- High load-carrying capacity

- Protects against rust and corrosion

- Good resistance to water washout

- NLGI GC-LB-certified

- Refer to TDS for NLGI availability

MEGAPLEX® XD3 (NLGI #1 & #2)

Megaplex XD3 is a high-performance, multipurpose, extreme pressure (EP) lithium complex grease developed to satisfy the severe lubrication requirements of construction and off-road equipment manufactured by Caterpillar, Komatsu Dresser, Case New Holland, John Deere and others. It is particularly recommended for use in off-highway trucks and heavy equipment, such as excavators, bulldozers, motor graders and wheel loaders operating under heavy or shock loads.

MEETS OR EXCEEDS THE REQUIREMENTS OF:

- Caterpillar Multipurpose Molybdenum Grease (MPGM)

APPLICATIONS:

- Chassis parts and wheel bearings of construction, mining and other heavy mobile equipment

- Universal joints, constant-velocity joints, brake self-adjusting screws and clutch-release bearings on off-highway trucks and other heavy equipment

- Tractor-trailer fifth wheels

- Heavily loaded plain and rolling-element bearings in industrial and mobile equipment where the manufacturer specifies a high temperature, extreme pressure grease with 3% moly

FEATURES/BENEFITS:

- High dropping point (>500°F)

- High load-carrying capacity

- Excellent wear protection

- Contains 3% moly for extra protection against galling and wear under shock loads

- Outstanding resistance to water washout

- Excellent resistance to oil separation

- Protects against rust and corrosion

- NLGI GC-LB-certified (NLGI Grade No. 1)

MEGAPLEX XD5 (NLGI #0, #1 & #2)

Megaplex XD5 is a high-performance, multipurpose, extreme pressure (EP), lithium complex grease developed to satisfy the severe lubrication requirements of mining and off-road equipment manufactured by Caterpillar, Terex, Komatsu Dresser, Le Tourneau, P&H and others.

MEETS OR EXCEEDS THE REQUIREMENTS OF:

- Caterpillar Multipurpose Molybdenum Grease (MPGM)

APPLICATIONS:

- Chassis parts and wheel bearings on mining and other off-highway equipment

- Hydraulic excavator mining shovels, such as Caterpillar 5100 and 5200 series

- Mine haul trucks

- Heavily loaded plain and rolling-element bearings in industrial and mobile equipment where the manufacturer specifies a high-temperature, EP grease with 5% moly

FEATURES/BENEFITS:

- High dropping point

- High load-carrying capacity

- Excellent wear protection

- Contains 5% moly for extra protection against galling and wear under shock loads

- Excellent resistance to water washout

- Excellent resistance to separation

- Protects against rust and corrosion

OMNIGUARD® 220 (NLGI #1 & #2)

Omniguard 220 is manufactured with high-quality base oils and an non-soap, calcium sulfonate thickener. It is fortified with EP and antiwear additives as well as rust and corrosion inhibitors.It offers superior protection against rust and corrosion in high-humidity, high-temperature applications such as those found in the steel, lumber, tire manufacturing and paper industries. It has excellent load-carrying capacity, high shear stability and outstanding resistance to water washout.

MEETS OR EXCEEDS THE REQUIREMENTS OF:

- NLGI GC-LB-certified for use as a multipurpose automotive wheel bearing and chassis lubricant

APPLICATIONS:

- Industrial and automotive equipment operating at high temperatures and exposed to water contamination, high humidity or corrosive environmental conditions

- Marine equipment, heavy mobile equipment and cables exposed to salt water

- Paper machine wet- and dry-end bearings and hot calendar stacks

- Rolling mills, hot roll tables, continuous casters, ingot buggies and slab mills

- Steel mill roller bearings, conveyors and gears

- Centralized lube systems and auto lubbers in service shops

FEATURES/BENEFITS:

- Excellent protection for new 2007 emissions-compliant engines and older diesel engines

- Specially formulated to protect exhaust aftertreatment devices

- Protects against particulate filter plugging

- Excellent soot control for protection against abrasive wear and soot-induced oil thickening

- Excellent resistance to viscosity and thermal breakdown at high temperatures

- Protects against sludge and varnish formation

- Protects against wear

- Protects against rust and bearing corrosion

- Good resistance to foaming and aeration

OMNIGUARD XD5 (NLGI #0, #1 & #2)

Omniguard XD5 is manufactured with high-quality base oils and a non-soap, calcium sulfonate thickener. It is compounded with select additives that provide EP and antiwear properties, excellent rust and corrosion protection, and excellent oxidation resistance. It is fortified with 5% molybdenum disulfide (moly) for extra wear protection under heavy or shock loads. Functional polymers provide better adhesion to metal surfaces and enhanced resistance to water washout in

wet environments.

APPLICATIONS:

- Chassis parts and wheel bearings

of mine haul trucks and other

off-highway equipment - Heavily loaded plain and rolling-element bearings in industrial and mobile equipment where the manufacturer specifies a high-temperature, EP grease with 5% moly

FEATURES/BENEFITS:

- High dropping point (>500°F)

- High load-carrying capacity

- Excellent wear protection

- Contains 5% moly for extra protection against galling and wear under shock loads

- Excellent oxidation resistance

- Excellent resistance to water washout

- Excellent rust and corrosion protection

OMNIGUARD FS XD5 (NLGI #1 & #2)

Omniguard FS XD5 is manufactured with

a low-viscosity synthetic polyalphaolefin (PAO) base oil and a non-soap, calcium sulfonate thickener. It is compounded with select additives to provide excellent oxidation resistance, EP and antiwear properties, and protection against rust and corrosion. It is fortified with 5% molybdenum disulfide (moly) for extra wear protection under conditions involving heavy or shock loading. The low-viscosity synthetic base oil provides outstanding pumpability at low temperatures.

APPLICATIONS:

- Off-road construction and mining equipment operating at moderate to very low temperatures

- Steering linkages, kingbolt bearings, pin joints, universal joints and other articulated chassis components

- Heavily loaded plain and rolling-element bearings in off-road equipment

- Conveyor and fan bearings in chemical and manufacturing plants that require a corrosion-resistant grease with moly

- Centralized lube systems

FEATURES/BENEFITS:

- High load-carrying capacity

- Excellent wear protection

- Contains 5% moly for extra protection against galling and wear under shock loads

- Outstandin

- Excellent resistance to water washout

- Protects against rust and corrosion

POLYTAC®

Polytac is a high-quality, multipurpose, non-extreme pressure (EP), polyurea grease developed for the lubrication of rolling-element bearings in high temperature, long life applications where extreme pressure protection is not required. It provides excellent oxidation resistance and high shear stability for long service life.

APPLICATIONS:

- Electric motor bearings

- Sealed-for-life bearings

- High-speed antifriction bearings

- Mill machinery

- Automotive and industrial applications

where a long-life, high-temperature, non-EP grease is required

FEATURES/BENEFITS:

- Excellent high temperature performance

- Outstanding shear stability

- Good wear protection

- Good resistance to water washout

- Excellent rust and corrosion protection

- Excellent low temperature pumpability

CABLE LUBE

Cable Lube1 is a heavy-duty lubricant developed for the lubrication and preservation of wire ropes and cables. It is formulated with a heavy residual base oil along with special rust and corrosion inhibitors, and is cut back with a volatile, non-chlorinated solvent for ease of application without heating.

APPLICATIONS:

- Wire ropes and cables

- Hoists, cranes and aerial tramways

- Logging and mining equipment

- Mill machinery

- Open and semi-enclosed gears and pinions

- Guides and sliding surfaces

FEATURES/BENEFITS:

- Good penetrating ability

- Preserves and conditions hemp cores

- Reduces friction and wear between

wire strands - Resists sling-off during high-

speed operation - Excellent resistance to water washout

- Excellent rust and corrosion protection

Note: Whenever possible, Cable Lube should be applied when the cable is flexing, such as when it is going over a sheave. This facilitates penetration of the lubricant to the core and permits more uniform coating of the wire strands. It is desirable, but not necessary, to clean the cable before application.